Dr. Tim Motis and his team at ECHO Florida have been testing bioliquid fertilizer recipes that were first identified in West Africa to better understand the timing and available nutrients over time. Letting the data tell the story allows ECHO’s training and resourcing teams to better equip and empower those we serve with validated knowledge that directly impacts their harvests and livelihoods.

By: Talia McWright

Soil health is key to growing crops that flourish and produce an abundance of food for communities. Dr. Tim Motis and his team at ECHO Florida have been testing bioliquid fertilizer to find out when to apply it. The team found that, with a recipe that includes plant material and manure, three is the magic number as nitrogen reached its highest level at the three-week mark. High levels of nitrogen are important because many farmers experience a deficiency of this nutrient in their soil. This is an example of discoveries, validated through research, that Dr. Motis and the ECHO team share with a global network of practitioners serving small-scale farmers.

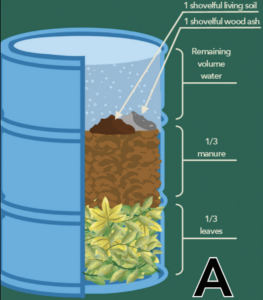

Originally identified in West Africa by a guest presenter at an event and shared with ECHO Florida, bioliquid fertilizer is a water-based fertilizer comprised mainly of nutrient-rich plants, manure, or both. Dr. Motis’ team has evaluated three recipes, all of which include water as well as leaves and young stems of a plant called Tithonia (Tithonia diversifolia, also known as Mexican Sunflower). One of the recipes is just water and Tithonia while the others include manure and/or “living soil” (soil with lots of microbial life) and wood ash. Other high-nutrient plants could potentially be substituted for Tithonia for similar results. Whereas compost requires careful attention to temperature and the turning of piles, the bioliquid fertilizer that Dr. Motis has been working with simply requires a few minutes of stirring each day.

The team collected samples of the bioliquid fertilizer over an 11-week period, on a weekly basis for the first several weeks, and then biweekly. The fertilizer samples were sent to a laboratory for analysis of nitrogen and other nutrients plants need. Results were then graphed to show how many weeks, after mixing up all the ingredients, it takes for the nutrients to reach their highest levels. Test results showed that nitrogen levels peaked at the two-to-three week mark, whereas levels of other nutrients reached their highest levels between the third and fifth week. Results showed that the best time to apply bioliquid fertilizer depends on the recipe and on what nutrients the farmer wants to prioritize.

Motis and his team are sharing results with the other Impact Centers so that they can be disseminated around the world. “With this knowledge, farmers will be able to decide when to apply bioliquid fertilizer based on the recipe they are using and the nutrients their plants need most,” Dr. Motis said.

Farmers with no access to manure can still make biofertilizer with just plant waste alone or in combination with “living soil” and wood ash. ECHO research findings not only showed when to apply bioliquid fertilizer but also the differences in nutrient levels provided by different recipes. If a farmer uses a recipe that is less nutrient-rich than another recipe, she/he will know to compensate by applying that recipe at a higher rate.

“There’s no simple technique to solve every plant problem,” Dr. Motis said. “There’s no silver bullet, but this is a practical option in a farmer’s toolbox.”

One downside of bioliquid fertilizer is its weight. It could be tiring to carry and apply a heavy liquid over large fields. A method used by ECHO Florida staff, that overcomes the problem of weight, is called fertigation. With the turning on of a valve, the bioliquid is quickly distributed directly to the plants through drip irrigation lines.

Dr. Motis’ team continues to explore nuances and options related to bioliquid fertilizer. Findings by Dr. Guin Perry, for instance, are showing the importance of wood ash in stabilizing the pH of the fertilizer, an important factor influencing the ability of plants to take up nutrients. She is also exploring an approach to making bioliquid fertilizer that eliminates the need for daily stirring. ECHO researchers hope to provide a range of on-farm fertilizer options that farmers can implement themselves to positively impact their communities by meeting hunger needs. The results will empower farmers to experiment, encouraging their communities to do the same.

Taking this validated research back to West Africa gives the team even more confidence in the practices that they teach.